Yushi Instruments is a fast-growing thickness gauge manufacturer in the China. We strive for high-tech thickness measurement technology to solve various thickness measurement problems. UM-4 series is a new generation thickness gauge launched by Yushi Instruments, which greatly improves the performance of the previous ultrasonic thickness gauge, and has better measurement stability and repeatability. It is widely used in the wall thickness measurement of pipelines, pressure vessels and storage tanks in petrochemical, electric power, shipbuilding and manufacturing industries.

● Economical full digital thickness gauge

The full-digital thickness gauge needs to convert the analog ultrasonic signal into a digital signal, then perform arithmetic processing on the digital signal, and finally obtain high-performance thickness measurement capability. The A-scan snapshot function, zero-crossing measurement technology, and high resolution of the UM-4 series are all based on full digital technology.

● Innovative A-scan snapshot function, marks the entry of all-digital era

The A-scansnapshot waveform display function provided by UM-4 series thickness gauge make the ultrasound no longer an invisible and intangible abstract concept. Users can see the ultrasound signal waveform on the screen directly to verify whether the thickness reading is correct, analyze the cause of the problem, Help users find solutions to problems.

● Breakthrough zero-crossing measurement technology

Based on full-digital technology and adopting zero-crossing measurement technology, the thickness measurement value can not be affected by echo strength, material attenuation coefficient, gain and gate height, and has high measurement stability and reliability.

● Through Coating Function

We have already launched UM-1D and UM-2D thickness gauges with penetrating coating technology, which have been recognized and praised by users, and now the UM-4D and UM-4DL have the same function, which is achieved by measuring two continuous bottom echoes of the substrate.

There are more advantages in this mode:

1. Without zero calibration;

2. High stability, the measured value can not be affected by the pressure of the probe, the thickness of the coupling layer and the dust on the surface of the workpiece;

3. Zero drift.

● More practical features

◆ Gain: high, medium and low three gears adjustable;

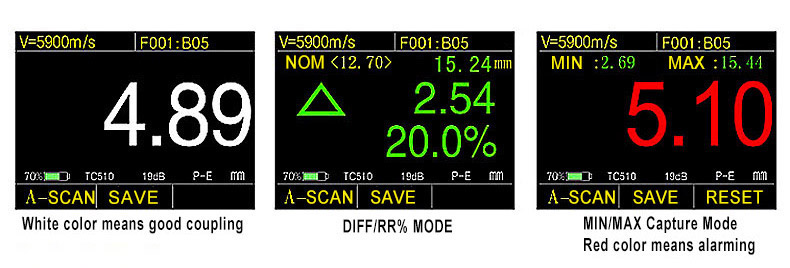

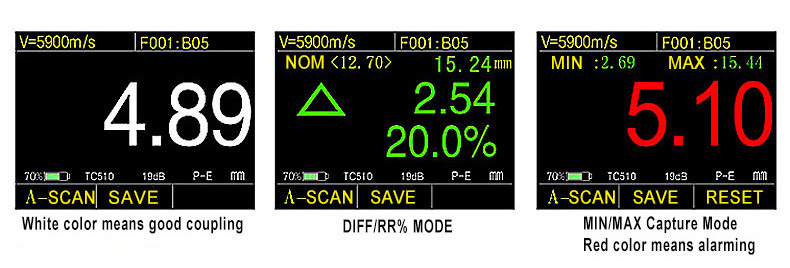

◆ Alarm mode: the thickness color changes dynamically when alarming;

◆ Difference/reduction rate: The difference mode displays the change in the difference between the measured thickness and the preset thickness. The reduction rate is to calculate and display the percentage of thickness reduction after the material getting thinner. A typical application is to measure metal materials that have become thinner due to bending;

◆ Maximum/minimum value capture: The current thickness value, minimum thickness value and maximum thickness value are simultaneously displayed on the screen.

Display | 2.4 inches color OLED, 320 X 240 pixels, contrast 10,000:1 |

Operating Principle | Pulse echo with dual element transducers |

Measuring Range | 0.60mm to 508mm(0.025" to 20.00"), depending on material, probe and surface condition |

Measuring Limits of Tube (Steel) | Φ20mm×3.0mm(Standard probe) |

Measuring Resolution | Selectable 0.01mm,0.1mm( 0.001",0.01") |

Units | Inch / mm |

Probe Calibration | One-Point Calibration, Two-Point Calibration |

Measuring Error | ±0.05mm (Low limit to 10mm) |

Update Rate | Selectable 4Hz, 8Hz, 16Hz |

Material Velocity Range | 500 to 9999m/s (0.0197 to 0.3937in/us) |

Stability of the Values | Based on full digital technology, with zero cross measurement technology, the measured value will not be affected by echo intensity, material attenuation coefficient, gain and the height of gate, keep high measurement stability and reliability. |

Repeatability | ±0.05mm |

Gain | Low, Medium or High for varying test conditions |

Display Mode | Normal, Minimum / Maximum capture, DIFF/RR% |

V-Path Correction | Automatic |

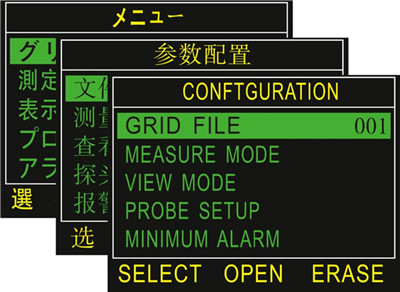

Languages | Selectable Chinese, English, Germany, etc. |

Alarm Settings | Minimum and Maximum alarms. Range of 0.25 mm to 508 mm (0.010" to 20.00"). |

Power | 2 AA size batteries |

Operating Time | Approximately 24 hours |

Instrument Shut-off | Selectable ALWAYS ON or AUTO OFF after 5, 10, 20 minutes of inactivity |

Operating Temperature | -10°C to +50°C (+10°F to +120°F) |

Size | 153mm × 76mm ×37mm(H × W × D) |

Warranty | 1 year |

Weight | 200g(including batteries) |

Standard Configuration | Ultrasonic Thickness Gauge,Standard Probe,Instrument Case,Couplant Bottle,Operating Manual, Certification, Packing List. |

Optional Accessories | Various Probes, Probe Cables, Step Calibration Blocks, Communication Software and Rubber Bumpers. |

Function Comparisions

Feature | UM-4 | UM-4D | UM-4DL |

Color Display | ü | ü | ü |

A-Scan Snapshot | ü | ü | ü |

Gain: Low, Medium, High | ü | ü | ü |

Min/Max Capture | ü | ü | ü |

DIFF/RR% | ü | ü | ü |

Thru-paint | X | ü | ü |

Data Logger | X | X | ü |

DataView Software | X | X | ü |

Optional Ultrasonic Probes

Model | PT08 | PT06 | PT04 | ZT12 | GT12 |

Type | Common | Small Tube | Fingertip | Cast iron | H-Temperature |

Frequency | 5MHZ | 7.5MHZ | 10MHZ | 2MHZ | 5MHZ |

Diameter | 11mm | 8mm | 6mm | 17mm | 15mm |

Range | 0.8-100mm | 0.8-30mm | 0.7-12mm | 4.0-508mm | 4.8-80mm |

Temperature | -10 ~70℃ | -10 ~70℃ | -10 ~70℃ | -10 ~70℃ | -20 ~450℃ |